Vibration and tilting detection is vital for public safety, early fault detection, predictive maintenance, and overall machinery health. By monitoring vibration and tilting in equipment, operators can identify potential issues before they escalate, reduce downtime, and extend equipment life. It also plays a vital role in infrastructure monitoring and earthquake detection, helping pinpoint structural weaknesses and providing timely seismic alerts to maintenance teams.

Vibration Detection Methods with TPS Devices

Use a Tibbo Modbus Sensor aka Bus Probe (BP)

Measures: Acceleration and tilt angle.

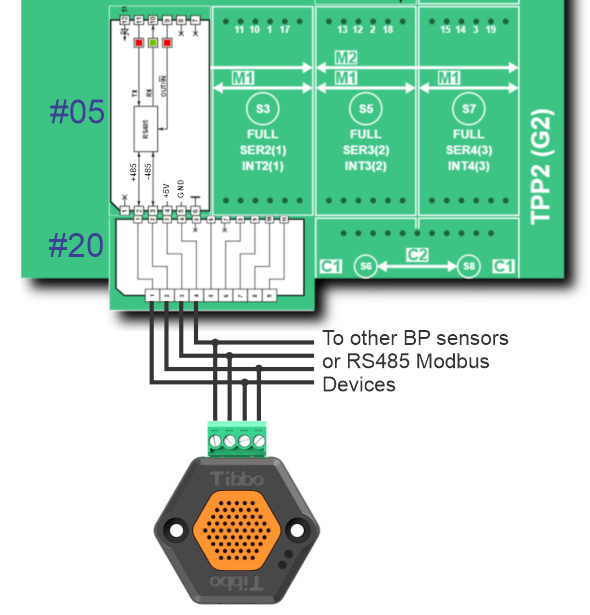

Tibbo Bus Probe #04, allows you to measure acceleration and tilt angle at significant distances from a TPS device. The probe communicates over RS485 using the Modbus RTU protocol. You can place it as far as 50 meters (160') away, and multiple probes can share a single RS485 bus. Module #05 handles RS485 communications and also supplies power. Connector Tibbit #20 (or #21) provides the necessary terminal blocks.

Schematic:

Pros:

- May be placed up to 50 m (160') from the TPS device.

- Multiple Bus Probes can operate on a single RS485 bus.

Use a Third-Party Modbus Sensor

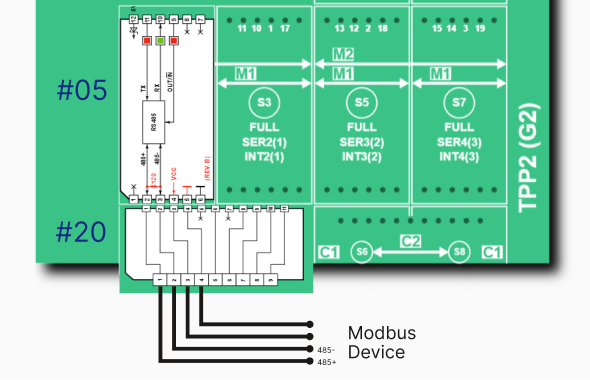

AppBlocks and TPS devices offer strong support for third-party Modbus equipment, so almost any RS485 Modbus device can be connected to a TPS unit. Use the Module Tibbit #02 or #05 for RS485 and the Connector Tibbit #20 (or #21) for terminal connections. You will also need to power your Modbus device. Tibbit #05 has a low-power +5V output, which is sufficient for our Bus Probes, but other Modbus devices may have different power requirements.

Schematic:

For Modbus devices with power requirements higher than 5V, you may also supply your own power.

Pros:

- Complete flexibility in choosing the Modbus sensor.

Cons:

- You will need to manually configure the sensor’s Modbus registers and data conversion within your AppBlocks application.

Tutorial:

Click here to learn how to work with slave Modbus devices in AppBlocks.