Nutrient supply control is the process of monitoring and regulating the delivery of essential nutrients within industrial, agricultural, or laboratory systems such as hydroponic farms, bioreactors, and water treatment plants. Maintaining precise nutrient levels is crucial for optimal growth, chemical balance, and overall system performance. This control is typically achieved through the use of nutrient sensors, dosing pumps, and automated control systems.

Nutrient Supply Control Methods with TPS Devices

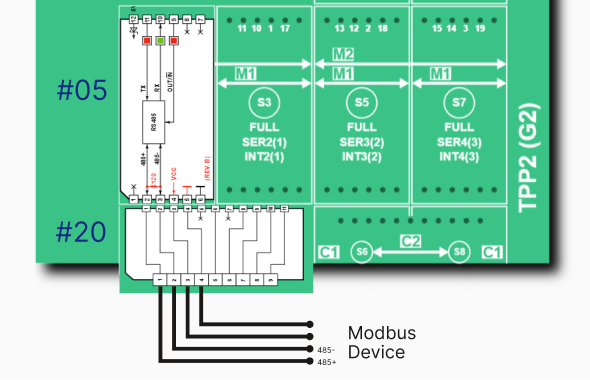

Use a Third-Party Modbus Pump

AppBlocks and TPS devices offer strong support for third-party Modbus equipment, so almost any RS485 Modbus device, including pumps can be connected to a TPS unit. Use the Module Tibbit #02 or #05 for RS485 and the Connector Tibbit #20 (or #21) for terminal connections. You will also need to power your Modbus device. Tibbit #05 has a low-power +5V output, which is sufficient for our Bus Probes, but other Modbus devices may have different power requirements.

Schematic:

For Modbus devices with power requirements higher than 5V, you may also supply your own power.

Tutorial:

Click here to learn how to work with slave Modbus devices in AppBlocks.

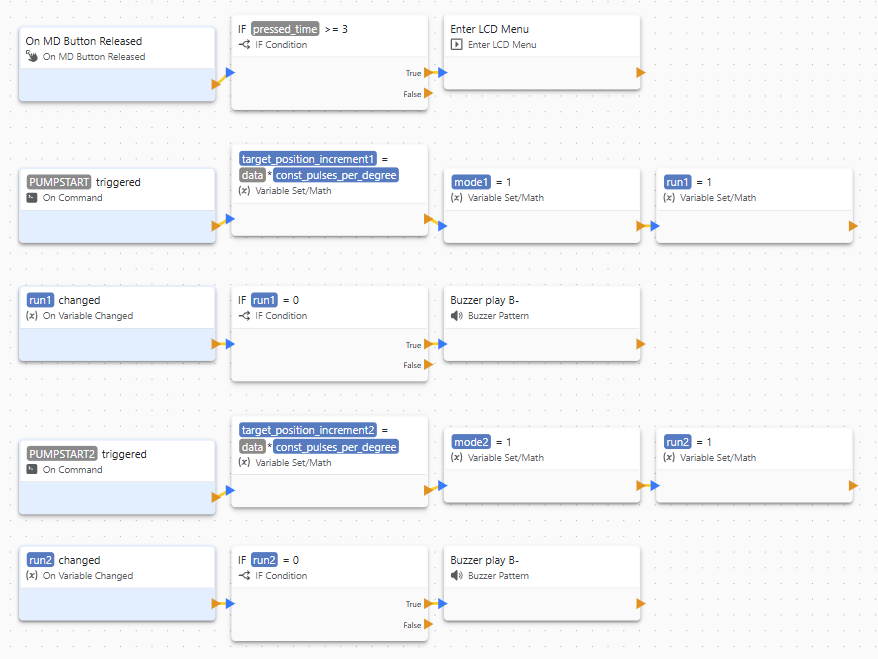

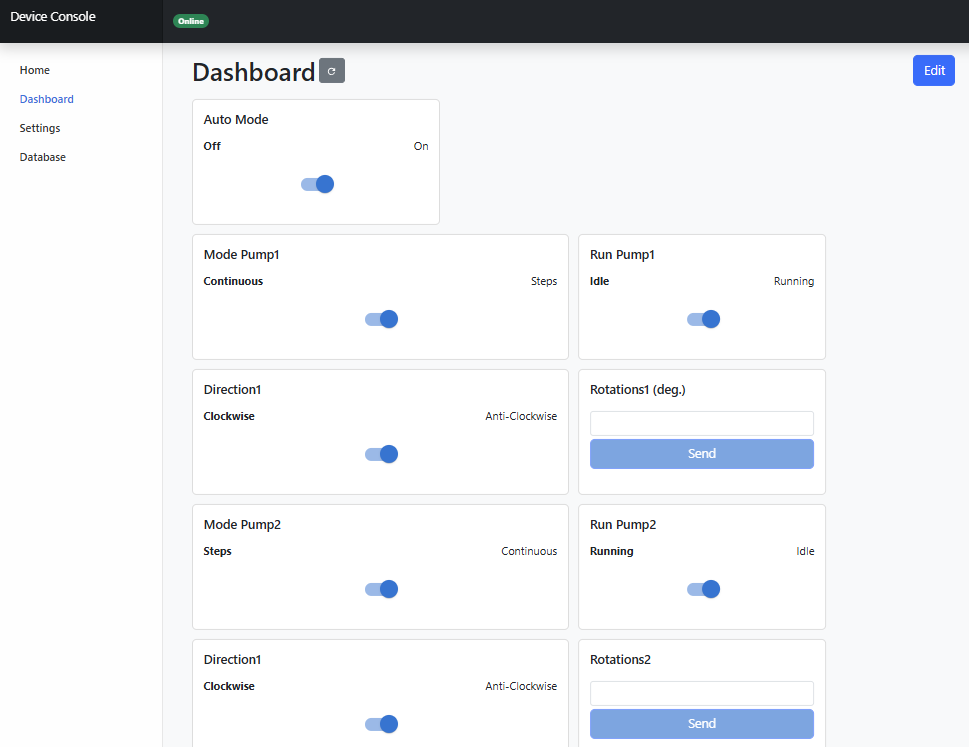

Example:

Click here to see an example project that uses a Modbus peristaltic pump (stepper motor) to control liquid nutrients via an AppBlocks Cloud dashboard.

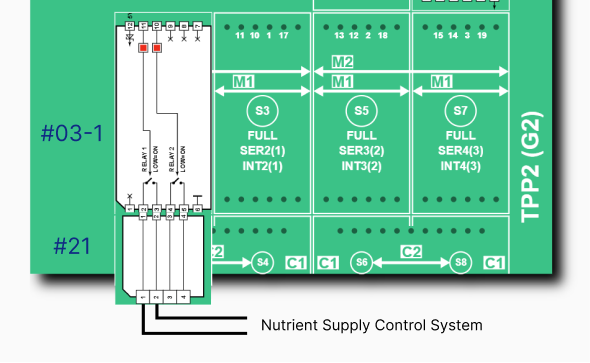

Use a Relay Tibbit

Controls: Relay.

Lots of nutrient control equipment such as solenoid valves, motorized ball valves and pump starters can be controlled using relays. Relay Tibbits, such as #03, #06, #07, and #15, provide straightforward, reliable relay control directly from a TPS device, enabling seamless integration with a wide range of devices. By connecting a relay output to the control input of a nutrient control system, TPS can effectively automate the supply of nutrients.

Schematic: